For the second year in a row Gartner lists digital twins as one of their top 10 strategic technology trends, labelling the concept as a game changer for manufacturing, customer service and marketing professionals. Being a digital replica of a company’s assets, digital twins could potentially improve enterprise decision making through real-time data acquisition, visualization and analytics. In this article, I’ll take a closer look at the relationship between the development of the digital twin technology and further adoption of the Industrial Internet of Things.

Digital Twins as a Foundation for IoT-based Products & Services

The development of an IoT solution is a complex process which involves many phases including analysis, Proof of Concept, prototyping, actual development, testing and production. A connected gadget often spends anything between 6 and 24 months in those stages until the desired performance is achieved.

As IBM put it, “the traditional engineer’s toolbox looks rather empty” when it comes to innovative hardware design and the Internet of Things software development. That’s why flawed IoT products – including devices with compromised Intel chips and 3rd-party APIs that are no longer patched by their vendors – are still released to the market.

Thanks to the digital twin technology, IT specialists can now gain a better insight into how elaborate IIoT systems function under the hood, run simulations before a connected device is even built and future-proof enterprise technology solutions.

https://www.youtube.com/watch?v=RaOejcczPas&feature=youtu.be

What Exactly are Digital Twins & How Can Your Company Benefit from Using the New Technology

As I mentioned earlier, a digital twin is a copy of a physical object or system; the complexity of such virtualizations ranges from stand-alone gadgets to entire factories or cities. The virtual counterparts are created on the basis of data which is collected through motion, light, temperature and spatial sensors, processed in the cloud and visualized – often with the help of immersive technologies including Augmented and Virtual Reality. Thus, a company that makes use of a 3rd-party digital twin solution (Microsoft, GE, Oracle, etc.) or has partnered with a custom software development firm to build a custom one can see whether the data matches their initial assumptions and take timely steps to transform their business.

Smart sensors, for instance, can be placed on agricultural equipment to help farmers prevent downtime, optimize fuel consumption and cut fertilizer use. Kaeser, a company that produces compressed air and vacuum products, has created a digital twin network to monitor equipment performance in real time and reduced commodity costs by 30%. And there is GE’s digital wind farm project based around sensor data processing and performance optimization; the approach reportedly helps wind farm companies increase energy production by up to 20% and generate extra $100 million in revenue over a turbine’s lifetime.

That being said, digital twins are not created equal.

According to Oracle, it is necessary to distinguish between a traditional digital twin which contains a detailed description of a system, 3D visualizations and data acquisition tools and predictive digital twins with Machine Learning capabilities which simulate mission-critical processes using historical data collected by other devices. Microsoft has also introduced the concept of process digital twins; as the term implies, businesses can use the technology to model processes – for instance, manufacturing and supply chain management.

Regardless of the approach, digital twins allow companies to

- Learn how users interact with a product and how the product in question performs in real-world environments (compared to tests conducted under ideal circumstances).

- Achieve greater transparency in asset management.

- Make data-driven business decisions when evaluating equipment performance.

- Troubleshoot remote equipment.

- Connect parts of complex enterprise systems.

- Continuously optimize product feature set to meet customer requirements.

Why IIoT Future Depends on the Digital Twin Technology

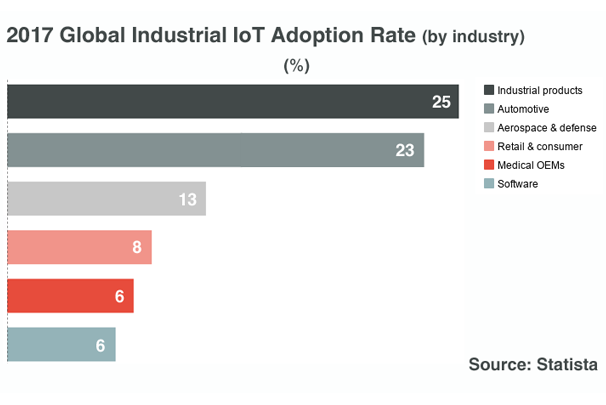

Led by manufacturing and automotive companies, the Industrial Internet of Things last year’s adoption rates varied from 25% to 3% across different industries. By 2021, the global IIoT market could potentially top $123 billion; meanwhile, half of prominent industrial companies will implement the digital twin technology to boost the outcomes of their IIoT initiatives.

It’s hardly a coincidence that the two technologies intertwine, bringing businesses closer to the automation- and analytics-driven future.

Digital twins – especially those powered by AI algorithms – will help companies stay ahead of the curve by shedding light on the ever-changing customer expectations.

Engineers can play digital twins forward or backward in time to figure out how an IIoT solution should work before it’s deployed physically and take proactive approach to emergency management, which is crucial in the age of IoT botnets capable of bringing down enterprise IT infrastructures and triggering mass blackouts.

Last but not least, the new technology will allow companies to assess IIoT development and deployment costs early on and thus avoid project budget overruns – one of top 5 reasons why 75% of IoT projects fail outright.

About the Author: Andrei Klubnikin is Senior Content Manager at R-Style Lab – IoT software development company with a business office in San Francisco, California. Andrei has been a tech blogger since 2011 and currently writes for Clutch.co, Business.com, IoT for All, DZone, Smashing Drones, etc.