Resin 3D printing is the name given for a class of additive manufacturing technologies that helps in curing liquid photopolymers for building an object by each layer. Resin printing isn’t the official term for the entire group, people it’s easier to call that because the machines will require resin materials.

There are several kinds of 3D printing technologies existing in the market that use liquid resins. The common factors among them would be –

- All of them use a photopolymerization principle for creating objects

- All of them work specific to a code

- All of them use resins as materials

- All of them use materials that need to be stored in a vat

Photopolymerization is the name used for a chemical reaction undergone by a special liquid that will change its properties once exposed to light (laser, UV, etc.). Such fluids are referred to as light-activated resins or photopolymers. In 3D printing, it is called resins.

There are several effects and types of photopolymerization reactions, but 3D printing uses the solidification effect of the liquid resin in the exposure to a light source. Light sources are quite different – LCD screens, projectors, lasers, etc.

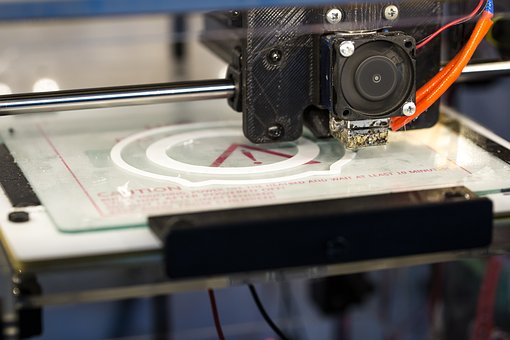

Resin 3D printers are known for having a light source. Other features and tools of the printer will vary depending on the technology.

Resin 3D printers will be able to form objects upside down or normally, depending on the positioning of the components. The upside-down orientation is known for being quite common with desktop machines as they can be operated easily and fabricated without losing out on the quality. The main factor with upside-down resin printers would be the supporting structures and print adhesion because the gravitation pull might prevent a part from falling down.

How Does It Work?

- For starting the printing with resin filaments, there has to be a resin tank that has the material filled automatically or manually. It is essential to avoid skin contact with resin as a few of them are known to be toxic.

- The machine will later lift the build platform for creating a thin layer of resin getting in touch with the build plate. Then, a light source will be drawing a single layer pattern in the resin, which could make help in the solidification process.

- The platform will then move for allowing the non-solid resin to come out and again form another thin layer on top of the plate. A roller can also be used for ensuring that the resin is lying perfectly.

These steps keep on repeating until the entire object gets formed. After the object is made, it is taken out of the machine for post-processing.

Different Kinds of Post-Processing Methods

Contrary to most 3D printing methods, resin printing requires a minimum amount of post-processing. Some of the steps to get the object ready would include –

- Washing – This method is necessary for removing uncured resin that might be left on the print. As the material is in the liquid form, it will flow over the object and build plate. Therefore, the prints will be put in water or alcohol or left to dry on a paper.

- UV-Curing – In this step, the object will be kept under a UV-lamp or sunlight for strengthening the object. During the printing process, every layer will be kept under light for a few seconds.

- Supports Removal – This step involves the removal of all the supporting structures that the object will contain. In the printing process, the supports will be required for holding the object, making it stick to a build plate, and preventing it from falling inside the resin tank during the printing process. There are quite many supports that hold every part, in spite of the knowledge that they can be removed quite easily. The whole process is careful and time-consuming one.

There are other techniques as well that are used for post-processing. They include –

- Sanding – This process is for removing taps from the places where the support was touching the object to help smoothen the surface. It is usually done using wet sanding or dry sanding tools. Wet sanding uses polishers or special liquids.

- Polishing – Various compounds are used for making the surface clearer and smoother, especially for bring transparency after sanding.

- Painting – It can be done using a variety of compositions and colours for special requirements.

Materials to Print

Resin 3D printers are known for curing liquid photopolymers. The manufacturing process of resin is quite different, and hence, the final product will be based on the prototyping and manufacturing needs. When it comes to printing with resin filaments, let’s take a look at the kind of prints formed using the different 3D printers.

- Standard Resin – It is an average photopolymer that is useful for most applications. The objects are solid, tough, and comes with a rubbery texture. The translucent resin is the easiest to work with because of its orange colour and its sensitivity to UV light.

- Glass-Reinforced Resin – This kind will have glass additives for providing more strength. Prints are usually tough and rigid and resistant to wear and tear.

- Durable Resin – This type is meant for parts that are going to be exposed to mechanical stress and will require some flexibility.

- Flexible Resin – It has the ‘rubber’ element that is known for great flexibility and elasticity.

These are some of the aspects that you need to be aware of regarding resin 3D printing. It is a technology that is different from the other 3D printing technologies, and the intricacies are discussed for developing a better understanding.